软件开发中经常遇到这样的问题:Bug 修了又出现,流程改了又乱,质量提升总是昙花一现。这些问题的根源往往不是技术能力不足,而是缺乏系统化的改进方法。

本文整理了工程管理中常用的质量改进方法论,包括 PDCA、5W1H、FMEA、六西格玛等。这些方法论虽然起源于制造业,但其核心思想同样适用于软件工程。

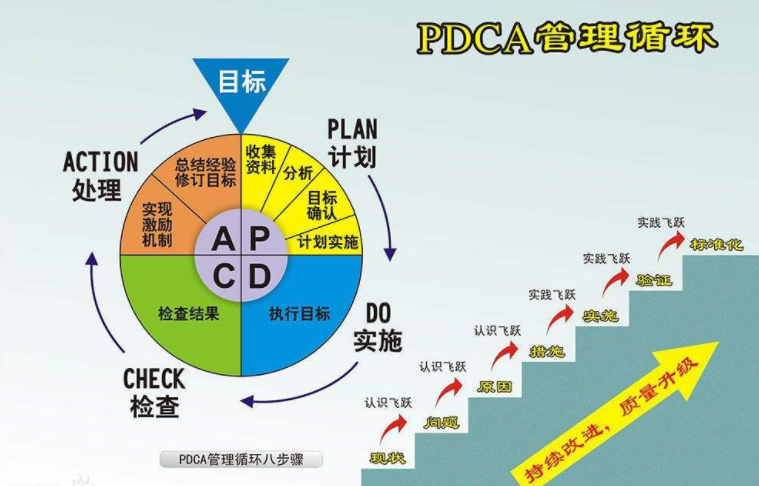

PDCA 循环:持续改进的基础框架

PDCA(Plan-Do-Check-Act)又称戴明环,是最基础的持续改进方法。它的核心思想是:改进不是一次性的,而是循环往复的过程。

| 阶段 | 核心动作 | 软件工程示例 |

|---|---|---|

| 计划(Plan) | 确定目标,制定方案 | 分析线上故障频发原因,制定监控告警优化方案 |

| 执行(Do) | 小范围试点实施 | 在测试环境部署新的监控规则 |

| 检查(Check) | 评估效果,收集数据 | 对比告警准确率和故障发现时间 |

| 行动(Act) | 固化成功经验,调整不足 | 推广到生产环境,更新运维手册 |

常见误区

- 计划阶段敷衍:没有明确的目标和衡量标准,导致后续无法评估效果

- 跳过检查阶段:执行完就结束,不验证效果,改进变成形式主义

- 不进入下一轮循环:一次改进后停止,没有持续优化

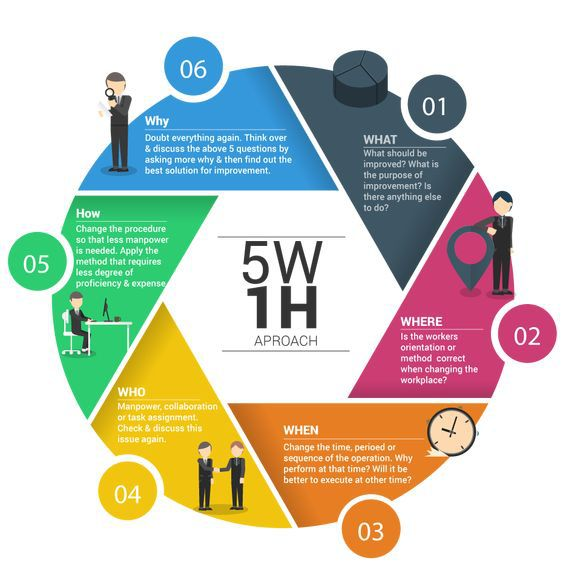

5W1H 分析法:问题定义的利器

5W1H 是问题分析的基础工具,通过六个问题全面定义问题边界。

| 问题 | 含义 | 示例 |

|---|---|---|

| What | 发生了什么问题 | 用户支付成功但订单状态未更新 |

| Why | 为什么会发生 | 支付回调处理超时,消息丢失 |

| Who | 涉及哪些人/系统 | 支付网关、订单服务、消息队列 |

| Where | 问题发生在哪里 | 订单服务的回调处理模块 |

| When | 什么时候发生 | 高峰期,QPS 超过 1000 时 |

| How | 如何解决 | 增加重试机制,引入消息持久化 |

常见误区

- 停留在表面:只回答 What,不深入分析 Why

- 遗漏关键问题:忽略 When 和 Where,导致无法复现问题

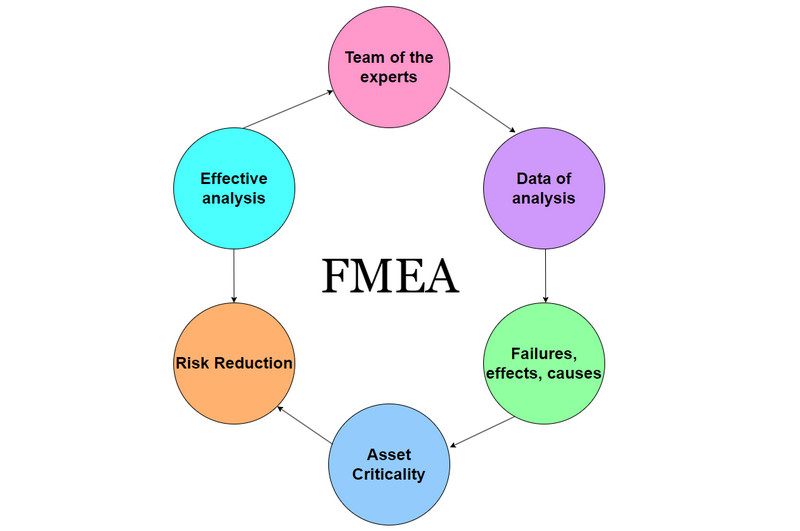

FMEA:故障模式与影响分析

FMEA(Failure Modes and Effects Analysis)是一种预防性的风险分析方法,核心是在问题发生前识别潜在故障点。

FMEA 的核心是计算风险优先数(RPN):

RPN = 严重性(S) × 发生频率(O) × 检测难度(D)每个维度用 1-10 打分,RPN 越高,优先级越高。

| 故障模式 | 影响 | 严重性 | 频率 | 检测难度 | RPN |

|---|---|---|---|---|---|

| 数据库连接池耗尽 | 服务不可用 | 9 | 4 | 3 | 108 |

| 缓存雪崩 | 数据库压力激增 | 8 | 3 | 5 | 120 |

| 配置错误 | 功能异常 | 6 | 5 | 4 | 120 |

常见误区

- 只关注高 RPN:低 RPN 的问题积累多了也会造成严重影响

- 评分标准不统一:不同人对同一问题打分差异大,需要团队对齐标准

六西格玛:数据驱动的质量改进

六西格玛的目标是将缺陷率控制在百万分之 3.4 以内。它的核心方法是 DMAIC:

| 阶段 | 核心动作 | 软件工程示例 |

|---|---|---|

| Define(定义) | 明确问题和目标 | 将接口错误率从 0.5% 降到 0.1% |

| Measure(测量) | 收集当前数据 | 统计各接口的错误类型和频率 |

| Analyze(分析) | 找出根本原因 | 发现 80% 错误来自参数校验不严格 |

| Improve(改进) | 实施解决方案 | 增强参数校验,增加单元测试覆盖 |

| Control(控制) | 建立监控机制 | 设置错误率告警,定期 review |

常见误区

- 认为只适用于制造业:六西格玛的数据驱动思想完全适用于软件质量管理

- 忽视 Control 阶段:改进后不建立监控,问题很快复发

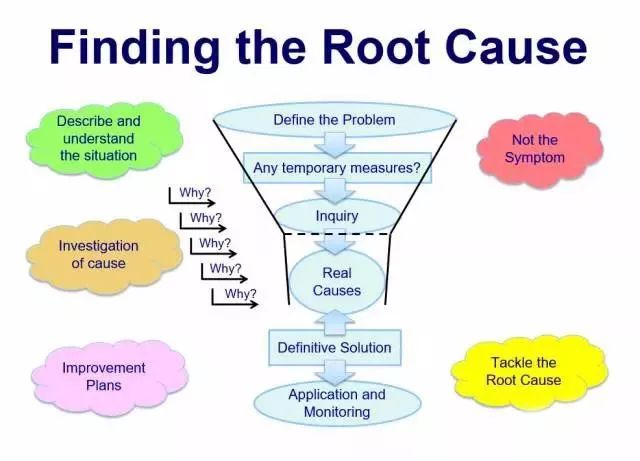

RCA:根本原因分析

RCA(Root Cause Analysis)的核心是「5 个为什么」——连续追问为什么,直到找到根本原因。

示例:线上服务宕机

- 为什么宕机?→ 内存溢出

- 为什么内存溢出?→ 对象没有被回收

- 为什么没被回收?→ 存在内存泄漏

- 为什么有内存泄漏?→ 连接池没有正确关闭

- 为什么没正确关闭?→ 异常处理代码遗漏了 finally 块

根本原因:代码 review 不严格,异常处理规范缺失。

常见误区

- 停在表面原因:只问 1-2 个为什么就停止

- 归咎于人:根本原因应该指向流程和系统,而不是个人

方法论选择指南

| 场景 | 推荐方法 | 原因 |

|---|---|---|

| 日常持续改进 | PDCA | 简单易用,适合小步快跑 |

| 问题定义和分析 | 5W1H + RCA | 全面定义问题,深挖根因 |

| 风险预防 | FMEA | 提前识别潜在故障点 |

| 系统性质量提升 | 六西格玛 | 数据驱动,效果可量化 |

总结

质量改进方法论的核心思想是相通的:

- 数据驱动:用数据说话,而不是凭感觉

- 根因分析:解决根本问题,而不是表面症状

- 持续改进:改进是循环往复的过程,不是一次性的

- 预防优于修复:在问题发生前识别风险

选择哪种方法论不重要,重要的是真正执行。一个被认真执行的简单方法,比一个被束之高阁的复杂方法有效得多。

AI周刊:大模型、智能体与产业动态追踪

AI周刊:大模型、智能体与产业动态追踪 程序员数学扫盲课

程序员数学扫盲课 冲浪推荐:AI工具与技术精选导航

冲浪推荐:AI工具与技术精选导航 Claude Code 全体系指南:AI 编程智能体实战

Claude Code 全体系指南:AI 编程智能体实战

最新评论

Flash版本的响应速度确实提升明显,但我在使用中发现对中文的理解偶尔会出现一些奇怪的错误,不知道是不是普遍现象?

遇到过类似问题,最后发现是网络环境的问题。建议加一个超时重试机制的示例代码。

谢谢分享,我是通过ChatGPT的索引找到这里来的。

十年打磨一个游戏确实罕见,这种专注度在快节奏的游戏行业很难得。从Braid到The Witness,每作都是精品。

快捷键冲突是个很实际的问题,我自己也被这个问题困扰过。最后通过自定义快捷键组合解决了。

会议摘要这个功能很实用,特别是对经常需要参加长会议的人。不过三次免费使用确实有点少了。

硕士背景转AI基础设施,这个路径其实挺常见的。建议多关注底层系统知识,而不只是模型应用层面。

配置虽然简单,但建议补充一下认证和加密的注意事项,避免被中间人攻击。